Repetier server plus#

What you get: An arduino compatible microcontroller, power cable, data cable, and a breadboard to build it on, plus a greater knowledge of soldering and circuitry.Best practices for resolving RepetierServer issuesĪ clean and tidy computer is the key requirement for avoiding problems with RepetierServer. Then you too can say, “I finally made something that works!”ĭate, Time, & Location: October 8th at the Space at Noon. Once you’ve completed this class, you’ll have you’re very own arduino compatible microcontroller, power cable, data cable, and breadboard to build it all on, the combination of which should help you save you from – oh no, I’ve already said too much! Hurry and sign-up on the events page at the following link. How many gigawatts is it? Where we’re going, we don’t need gigawatts, just bring a soldering iron and the rest will be provided. You don’t even need any plutonium to power this baby, just plug it straight into the breadboard that the Makers will be providing to all the class participants. An RBBB is one of the smallest, most affordable arduino-compatible boards available right now.

Repetier server how to#

Listen, I know this may sound “heavy” to you, but we’ve got to get you to the Midsouth Makers soldering class on October 8 th at noon or the consequences could be dire! I can’t tell you why it’s important without creating a temporal paradox, but I can promise you that learning how to build a RBBB (“Really Bare Bones Board”) Clone will be pivotal in your future in some way. Great Scott! What’s the date? Oh thank goodness, we’ve still got time. Please show our thanks and appreciation to LulzBot and the RepRap community! In order to have access to the 3D printer without one of us present you will need to have had verified prior experience with a RepRap 3D printer, or attended an upcoming class on running & troubleshooting 3D printers(TBD) or be able to demonstrate the appropriate knowledge. If you’d like to use it, please contact Claudio, Ben, Dan or Cliff- more information will follow. More information on the new 3D printer can be found in our wiki.

Nozzle Fan for printing in PLA installed but not hooked up.Integrated Filament Mount for either loose coiled filament or spindles for spooled filament.Borosilicate Glass Bed with PET film on one side for printing with ABS and bare glass on the other side for printing with PLA.Filament- Currently setup for 3mm and can reliably print the following material types:.Extrusion temperature range – 180C – 240C.

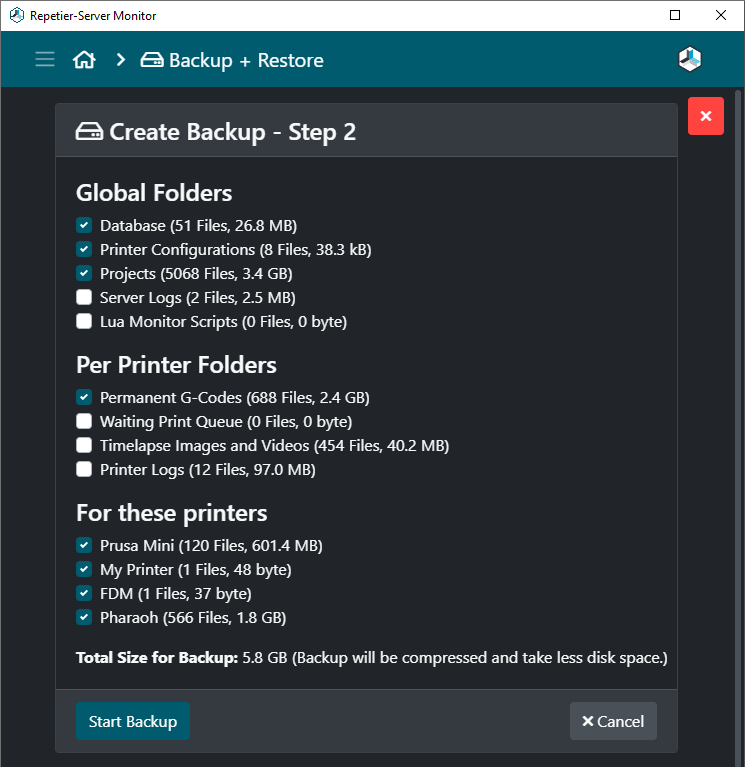

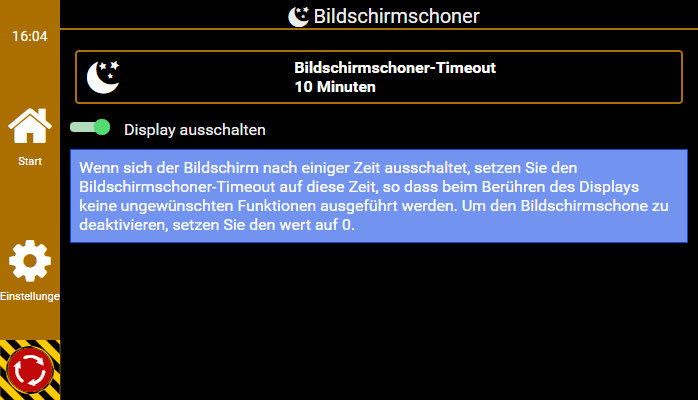

We will need the following items to get our new 3D printer setup and functional: We will be exploring webcam functionality for use in monitoring and in generating time-lapse print videos. Repetier-Server will allow you to load a gcode file and control the printer. The AO-101 will be using a donated a 1U server as the host computer. We recommend Repetier-Server due to it’s stability.

We have it setup to allow for remote printing on the LAN, using either OctoPrint or Repetier-Server. The AO-101 currently uses 3mm filament and can print in ABS, PLA, Nylon and even Laywoo-D3 wooden filament. Well thanks to a kind donation by LulzBot we now have a dedicated 3D printer at the space for member use! The printer is an AO-101, a MendelMax 1.5 variant. using and tweaking our 3D printers for a while now. If you’ve been following Midsouth Makers you know that we’ve been building.

0 kommentar(er)

0 kommentar(er)